Recent advances in technology have allowed engineers and designers to develop medical devices that are more sophisticated and complex than ever before.

For some manufacturers, these new requirements have been a challenge as they work to keep pace with increasing demands for precision and demonstrated quality. However, when experienced, multi-disciplined engineering teams collaborate to develop solutions, new levels of manufacturability and quality can be realized.

AVNA, a medical device component and assembly manufacturer, has made such an innovation in its metal tube end closing and forming processes.

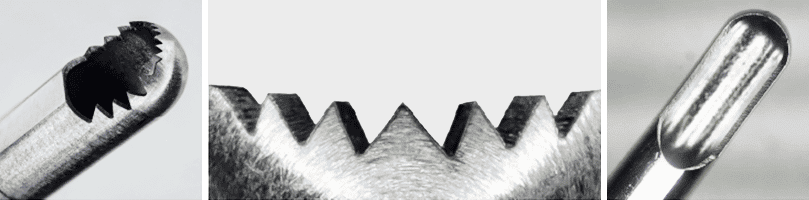

Medical components, such as high-speed microbride blades, sheaths, and shavers (used in a variety of arthroscopic, neurovascular, ENT, and gynecological procedures), are traditionally manufactured with joined metal components. For parts with strict rotating or oscillating requirements, the joining process may yield high scrap rates and greater tolerance variations, resulting in reduced instrument performance and increased risk of failure during the surgical procedure.

Through a custom-engineered combination of CNC machinery, technology, software, and automation, the AVNA team has developed an innovative tube end closing process that results in unmatched uniformity and balance, ultimately improving device functionality and performance. Leveraging the company’s NexTech Labs for prototype and process development,AVNA ’s in-house engineering team created the new, proprietary solution.

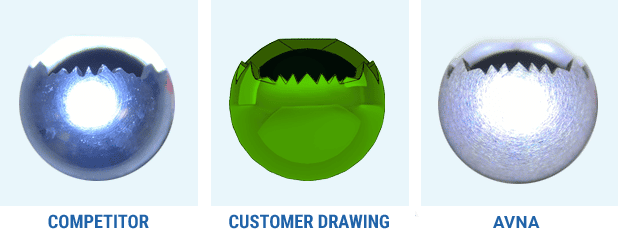

Their unique approach eliminates the use of an end cap or a secondary part, and instead efficiently forms standard tubing into complex spherical or elliptical end shapes. The process reduces the inherent dimensional and cosmetic defect modes when joining two parts, and results in a component with improved wall thickness uniformity, better end shape consistency, concentricity, balance, and stricter compliance to tight tolerances.

First, raw tubing is laser cut to a specified length, which then undergoes a cleaning operation. Tubes are then fed into a custom-built, 9-axis CNC machine. Robotic arms load the tubes onto two independent spindles, moving and inspecting each part during the entire process. Utilizing custom tooling and programming, the CNC equipment then executes a series of end forming operations, maintaining extremely tight tolerances in each procedure.

With the tube end formed and a leak-free seal achieved, AVNA then utilizes a robotic grinding system to complete the desired end closure geometry. This fully customizable multi-axis process helps to ensure straightness and produces a finished end tube with precise accuracy and superior surface finish.

Additional finishing steps of the closed end tube and forming process are dependent on customer specific requirements, and could include milling, drilling, laser cutting, wire EDM, or other machining methods.

Final finishing operations often include:

Throughout the process, quality controls efficiently monitor and validate part compliance. Automated vision systems, closed loop feedback systems, and CMMs (coordinate measuring machines) continually inspect parts, integrating technologies that automatically adjust in real-time to compensate for tool wear and to maintain tolerance. This helps ensure part accuracy and consistency throughout the entire manufacturing process.

OKAY’s innovative tube closing process produces medical device components with superior reliability and strength, while complying with extremely strict tolerance requirements. The highly efficient solution is especially valuable for medical device designs which require high RPM rotation. Parts are manufactured with less runout, translating to minimal vibration and reduced risk of failure or compromised performance when used in the surgical procedure.

Together, through collaboration with medical device OEMs, AVNA is helping to produce the next generation of medical solutions, supplying cost effective components with superior performance, quality, and reduced time to market.

To learn more about AVNA ’s metal tube end closing and forming process, contact us or schedule an appointment in our NexTech Labs. Discover how our customer-focused collaboration will improve outcomes of your next project.